Colour and Gloss Measurement Solutions for Quality Control of Automotive Interiors

Development, production, and QC solutions for control of the colour and appearance of interior plastics, carpets, metals, and leather

Automotive interiors include a variety of materials utilised in creating the cabin of modern automobiles. This includes plastics, textiles, metal, leather, and more.

Automotive interiors play a huge role in customer experience, branding, and positioning with these materials in direct contact with the customer and responsible for the perception of quality. The development and specification of these materials must be undertaken in parallel with the interior lighting in order to deliver an environment that is functional, projects quality, and avoids any undesired interactions between materials and light sources.

Digital colour and appearance data can be used to expedite the supply process, greatly improving an OEM’s ability to react to the market by reducing the costs and risks associated with producing, distributing, and maintaining physical standards.

The wide range of materials to be measured, including plastics, paint, textile, leather, glass, and metals, requires selection of the correct solution in terms of measurement geometry and usability.

Colour Measurement applied when visiting with supply partners, agreeing specifications, in development laboratories, in benchmarking against competitors or reporting for internal quality control programs can build supply relationships based on quality and consistency, reducing subjectivity in the colour production process.

Whether for development, process, or quality control for internal controls, colour specification, and communication with the supply chain, our expert team can help the automotive industry to accurately specify, produce, and communicate colour. Utilising Konica Minolta’s innovative and accurate measurement instruments with cutting edge software, producers can greatly improve the process, speed and outcomes of their colour workflow.

Konica Minolta and partner Rhopoint Instruments offer a compressive range of solutions to the automotive industry, aimed at producing consistent and quality components for the cabin. This helps automotive marques to improve the perceived quality of their products, ensuring a visually appealing interior environment by controlling the appearance of interior materials.

Konica Minolta has a dedicated team, experienced in delivering digital colour data systems to global supply chains, allowing organisations to specify and share colour standards with supply partners to centralise the colour matching, quality control, and approval of colours within their libraries. Our systems are supported by a global network of sales and expertise, and authorised service facilities that ensure your systems can be maintained with minimal downtime.

Benefits

- Save time and money with digital colour data by communicating digital colour standards directly from your library with supply chain partners, saving the cost and risk associated with physical master standards.

- Improve quality and lower working tolerances by centralising the colour supply chain and unifying suppliers on close tolerance colour measurement instruments.

- Reduce waste and save time by specifying and approving colours within a digital colour data system.

Instruments

Just Normlicht LED Color Viewing Light v8

LED based viewing light with standard illuminants for controlled viewing that can also be configured with user specified illuminants to match with effect lighting, ensuring that the combination of light and parts produces the desired visual effect for customers.

Applications

Case Study: Evaluation of high-quality appearance applications

Discover how the company Sanko Kasei Co., Ltd. improved their productivity by replacing their existing spectrophotometer and glossmeter to our CM-26dG. Simultaneous measurement of Colour and Gloss with 1 device significantly reduced the measuring time and improved their work efficiency.

Measurement of Interior Plastics

OEMs are able to specify the colour for interior plastics and share the digital colour standards with supply chain partners who can use the same system for colour recipe prediction and later perform QC measurements against that standard. By specifying digital colour data standards and measuring with close tolerance instruments from Konica Minolta Sensing, tolerances can be tighter, and timescales shortened.

The 45-degree geometry of the CM-25cG ensures that the operator can match colours to other parts, irrespective of surface texture. Circumferential illumination eliminates directional dependency to minimise the influence of measurement position and rotation, particularly in frosted, textured, or structured surfaces commonly used in automotive plastics.

Measurement of Leather

The target colour for upholstery leather can be specified to the correct supply chain partners to match. The producer can match to the required colour and use a portable spectrophotometer to measure production samples and establish working tolerances and provide QC data back to the specifier.

Measurement of Small Curved Surfaces

The portable spectrophotometer CM-700d has a small measuring aperture and vertical alignment that makes it ideally suited to measuring on small and curved parts which would otherwise be difficult to accurately position a measuring instrument on.

Gloss can also be measured on these small and curved surfaces using the Rhopoint glossmeters, either the Rhopoint Novo-Gloss FLEX 60 or the Rhopoint IQ FLEX 20-S.

Precision Appearance Measurement for Automotive Interiors

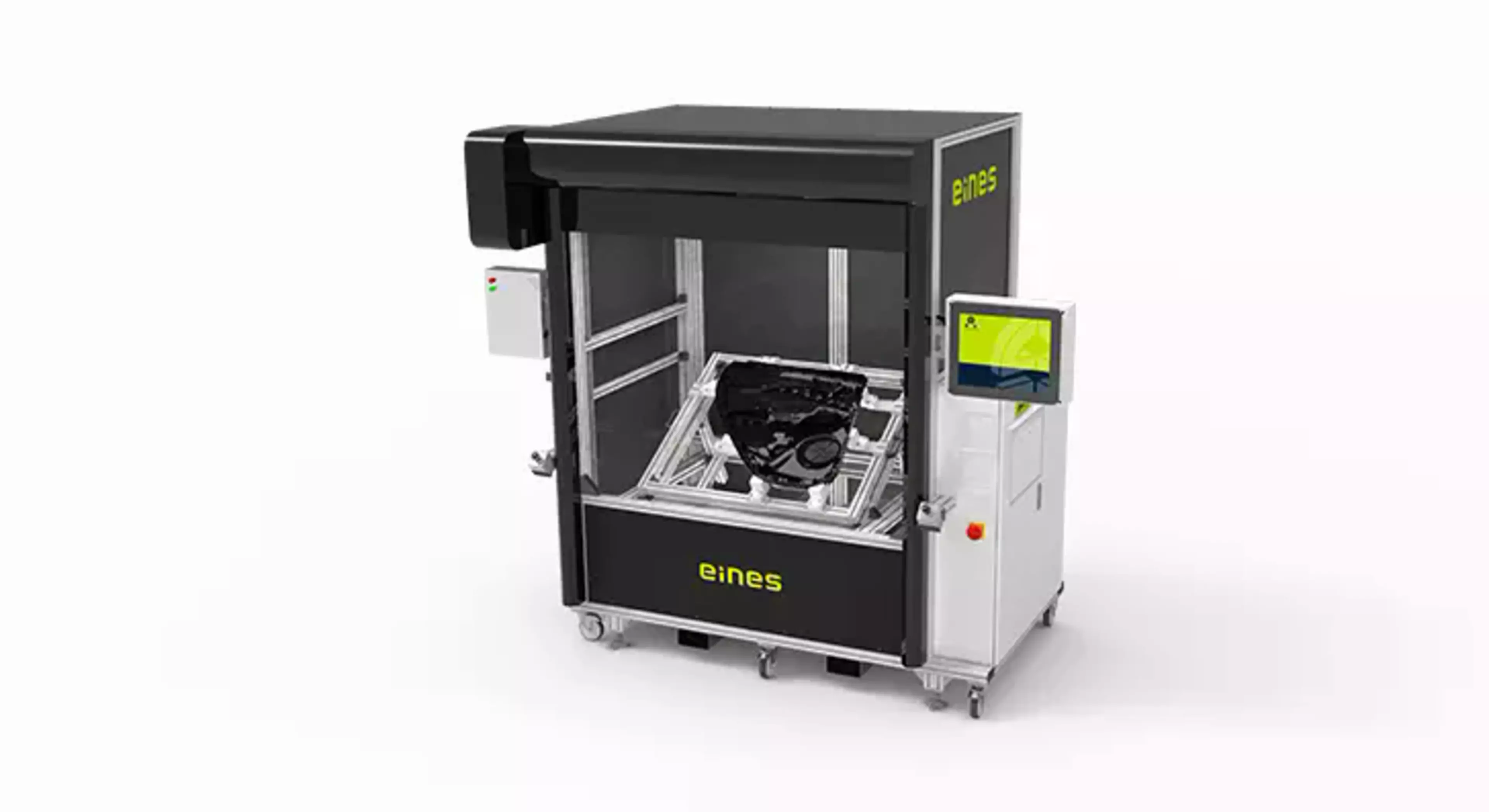

Rhopoint Aesthetix® machine vision device delivers high-accuracy, human-perception-aligned measurement of gloss, texture, haze, and more, ideal for evaluating complex surfaces in automotive interiors. Its modular design ensures seamless integration into QC processes.

CoboSense - Cobot Solutions for Visual Quality Inspection

Automate your surface inspection systems and integrate our measuring devices for consistent and accurate inspection.

Boost efficiency and ensure high-quality output to meet stringent quality control standards across industries.

CoboSense can be integrated into different kinds of testing workflows and scaled to suit various automated production processes.

Ask our experts