Colour and Gloss Measurement for Pulp and Paper Industry

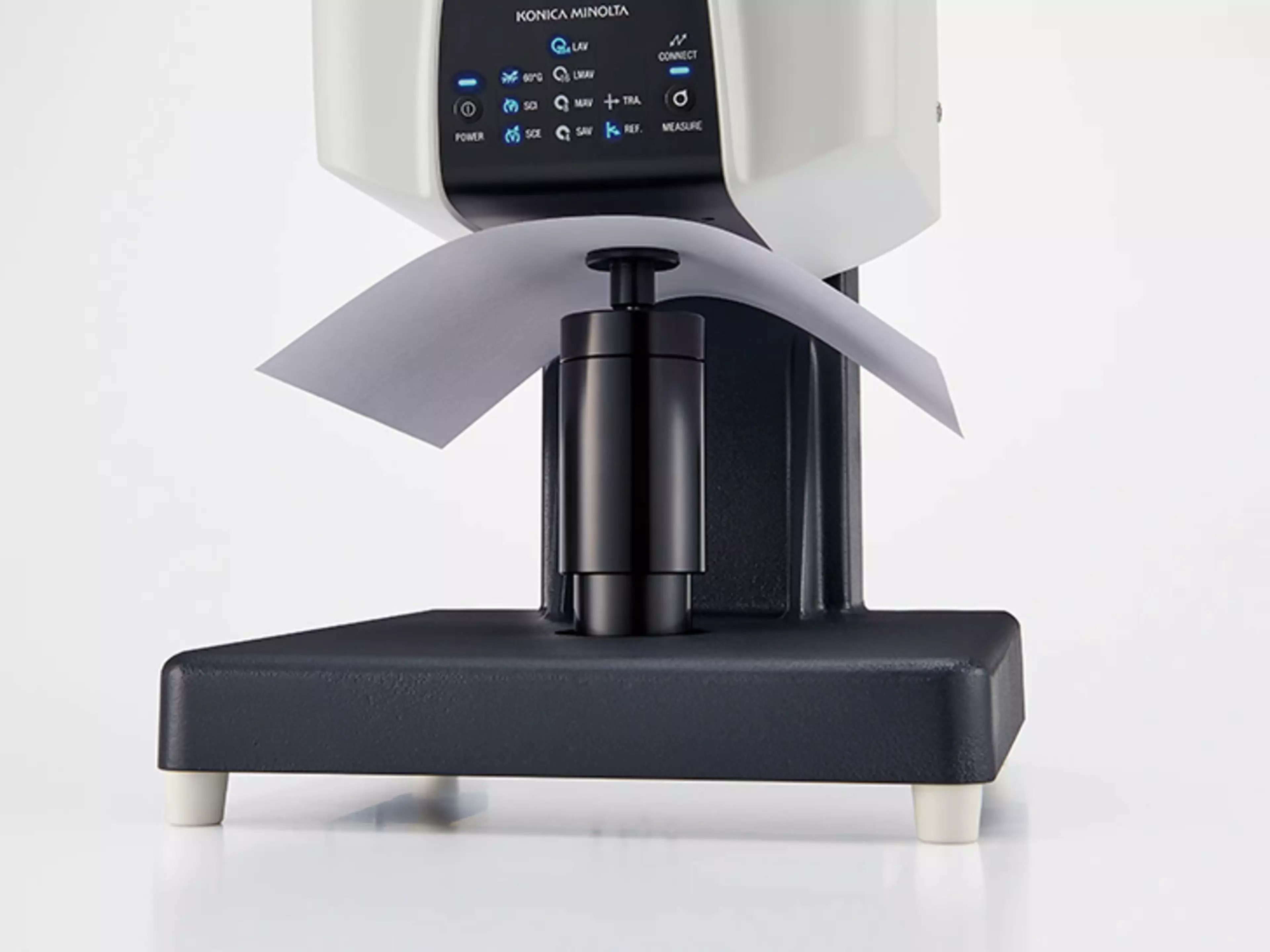

Konica Minolta Measuring Instruments offer traceable and trusted measurement technology for the paper industry, including ergonomic portable spectrophotometers, versatile benchtop spectrophotometers, and a range of controlled lighting colour viewing cabinets.

Scalable solutions are available to help organisations and their wider value chain to specify, communicate, produce, and control colour.

- Optimise processes

- Improve consistency

- Boost customer satisfaction

- Reduce waste

Colour measurement, using a spectrophotometer, will allow producers to manufacture a consistent product with control of optical brighteners. By controlling these parameters, manufacturers can build a reputation for quality with customers and ensure that specifications and tolerances can be met.

Colour control is a vital tool in the pulp and paper industry, for process control and quality control in order to deliver the most consistent experience for customers in packaging, craft, print, etc.

Konica Minolta has a global reach, with local sales and expertise to assist you in establishing a successful digital colour data system. Whether between supply chain partners, in development, in production or in QC, our teams can deliver a solution that meets your needs, and partner with you to scale that system as those requirements grow. Our colour matching software is supported by a dedicated team experienced in installation, training, and customization of the solution to optimise your colour workflows.

Konica Minolta measuring instruments are supported by an extensive network of authorised service facilities to ensure that your instrument is maintained, accurate and traceable all year round.

Benefits

Produce consistent quality: Batch to batch consistency improves end user satisfaction and perception of quality, reducing returns and waste.

Colour is a sales tool: Colour control and colour matching offer new possibilities for branded packaging products.

Colour is a service: The ability to offer colour data and consistency to customers marks you as a reliable partner who offers an added value service

Example Applications

Improve consistency and tighter tolerances paper products covering walls such as wallpapers, lining papers, etc., reducing waste and increasing the perceived quality of products.

Fulfil tighter tolerances on high added value packaging materials to improve customer satisfaction and the ability to reach new markets.

Improve QC approval speed and product sorting.

Ensure a greater control over quality of recycled paper products and colour data driven process improvements.