Ensure Quality of Projection Display

Measurement for projection display applications in cinema, training simulators, art installation and home theatre.

Projection display technology is designed to wow the observer with scale and impact. Whether delivering a visual cinematic experience that lives up to the vision of the director or delivering an immersive experience such as commercial flight simulation, the observer perception of quality requires calibration and control of brightness, contrast, colour and uniformity of the image that is projected onto the screen.

Projection systems are tested not only through development and production but also throughout their life through ongoing calibrations.

- Test and characterisation of internal LCD or DLP element

- Quality Control and Calibration of projected image in test and in-situ

Konica Minolta supply accurate and traceable light measurement instrumentation to manufacturers, installers and maintenance professionals to characterise:

- Uniformity of brightness ANSI brightness across the display,

- Contrast between the dark and light

- Calibration of colour

Konica Minolta Sensing supply a range of systems to meet these measurement requirements,

- from simple illuminance meters for measurement and calibration of illuminance at the screen,

- luminance meters for luminance and colour,

- spectroradiometers for point inspection of luminance and spectral power distribution data of the internal LCD or DLP unit,

- or an imaging colorimiter for uniformity analysis of the overall projected image.

The scale of projection technology creates an impact. Accurate measurement technology can help ensure that the viewer experience exceeds expectations.

Benefits

- Develop and validate quality performance and optimum customer experience with test and calibration systems for development, manufacture and ongoing calibration of projection technology.

- Traceable measurement solutions for all pricepoints from spot illuminance to imaging colorimeter.

- Ensure quality in-situ using versatile and portable technology

- Save time and simplify processes through integration to systems through software development kit

Instruments

Applications

Test and measurement of LCD and DLP

To ensure that their devices leave production delivering peak performance, our customer is using a CS-2000A spectroradiometer to measure spot luminance and colour at the component level directly on the DLP. In this instance the device is interfaced with local systems and software for calibration and adjustment. The CS-2000 can also be connected to Excel or its own software when used in a development environment.

The CS-2000 and CS-2000A have now been succeeded by the CS-3000 Spectroradiometer. The CS-3000 delivers improved accuracy and reduced measurement times, capable of measuring in as little as a quarter of the time of its predecessor for some lengthy low light tasks. The new instrument is also designed for improved system integration and automation.

Basic testing of projection technology in-situ

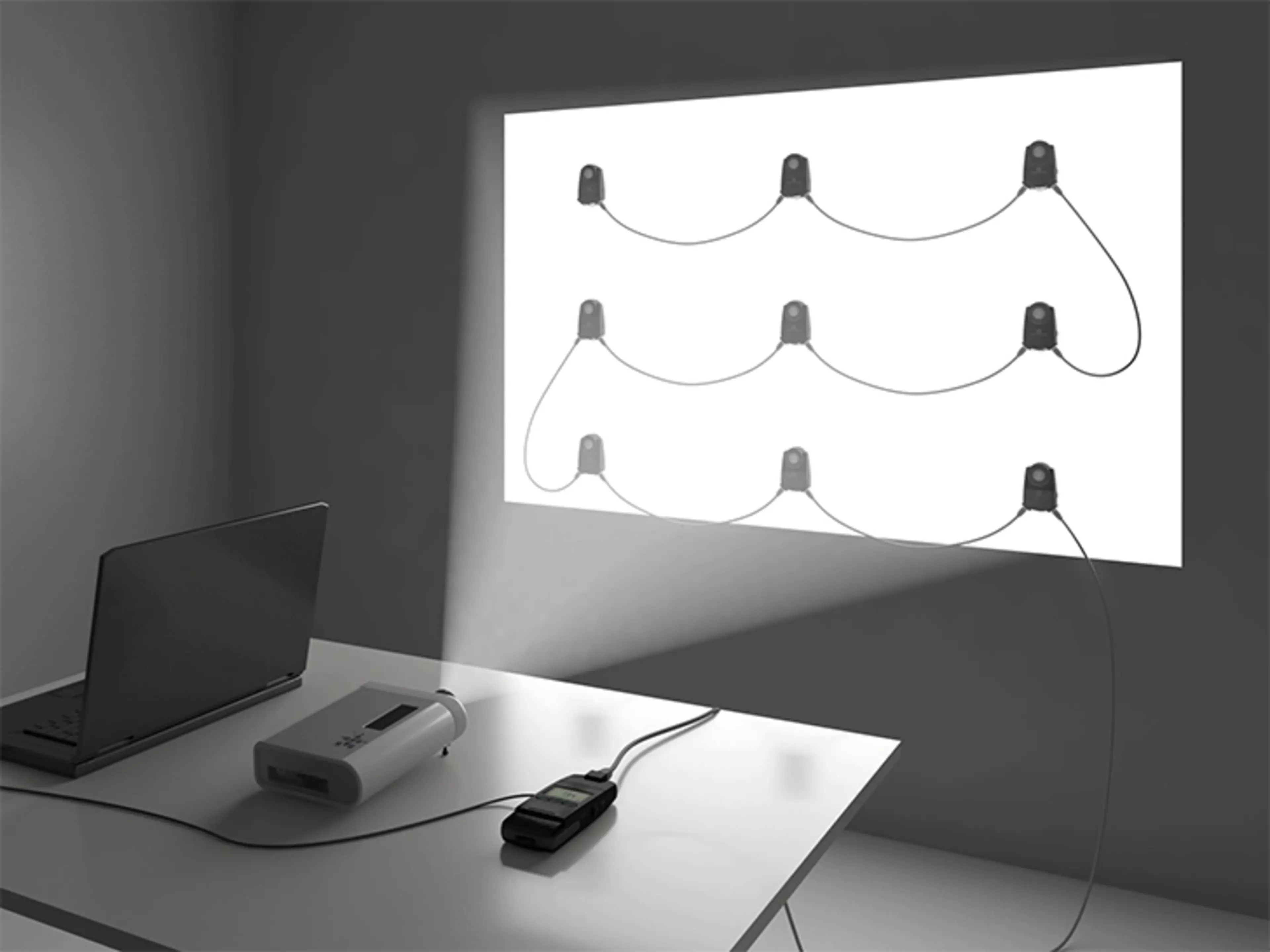

The T-10A can be used in a combination of upto 30 measurement heads to measure illuminance over a large area, it can also be used with a single receptor for in-situ maintenance and installation applications where the operator repositions between measurements. This can provide before and after validation of repairs or service.

The CL-200A or CL-700A (upto 15 devices) can be used in the same manner, providing additional value by measuring both colour and illuminance. This allows the operator to perform test and calibration of colour for in-situ projection technology.

Ask Our Experts