Colour Measurement for Powdered Pharmaceutical and Personal Care Products

Including pharmaceutical compounds, ingredients, and cosmetics to ensure batch consistency and high perceived quality.

Within the pharmaceutical and personal care products industries, powdered products represent a significant proportion of colour measurement applications, both in cosmetic powders but also as raw materials and as process steps on the way to finished products. To measure powdered products, or even granules and particle sizes in between, the sample is pressed to a flat and consistent surface, and measured in reflectance.

For powdered cosmetics, colour is used as a selling point; the ability to specify and produce new colours or match to seasonal trends is a source of competitive advantage. For pharmaceuticals the ability to make the colour of products "fit in" or meet expectation cannot be understated.

Digital colour and appearance data can be used to expedite the supply process, greatly improving companies' ability to react to the market by reducing the risks and costs associated with producing, distributing, and maintaining physical standards.

Colour measurement, applied when visiting with customers, agreeing specifications with suppliers, in product innovation development laboratories, benchmarking industry competitors, or reporting for internal quality control programs, can build supply chain relationships based on quality, consistency, and reducing subjectivity from specification and approval.

Providing a product with a high perceived quality that is consistent and matches the consumer expectation are core to the user experience and essential to brands within the industry, as well as the ability to offer a wide range of colour products and to react quickly to the market.

Our experts can help your teams to establish digital colour standards and colour difference tolerances that you can share with your supply chain partners. You can leverage the experience of our application teams to quickly establish repeatable, best-practice processes for colour and appearance measurement and control.

Konica Minolta measuring instruments can help producers to deliver accuracy, certainty, and traceability for the production of powdered materials. Our instruments and software are easy to use whilst providing vital colour and colour difference data to operators in development laboratories, in production, or in quality control. Whether used for goods in, development, process control, or quality control, implementing colour data and colour communication can help optimise processes and deliver a product with higher perceived quality. Our experts can help you to establish a system that will ultimately reduce waste, whether this is by improving communication and tolerances with suppliers, spotting production issues that cause deviations early and being able to cost effectively correct them, or removing subjectivity from QC processes.

Konica Minolta benchtop and portable spectrophotometers are widely used in the Pharmaceutical and Personal Care industries. The instrument selection will largely be down to your processes and any additional processes that you may need, for example whether it is also useful to measuring liquid products with the same device. Our experienced teams can recommend a solution, and our extensive service network can ensure that your instruments are maintained and traceable throughout their life.

Benefits

- Attract attention in retail (or "fit in" with established products)

- Achieve consistency within production

- Extend existing product ranges

- Alter existing recipes or replace components without changing the perceived high quality or original colour

Instruments

CM-5 Benchtop Spectrophotometer

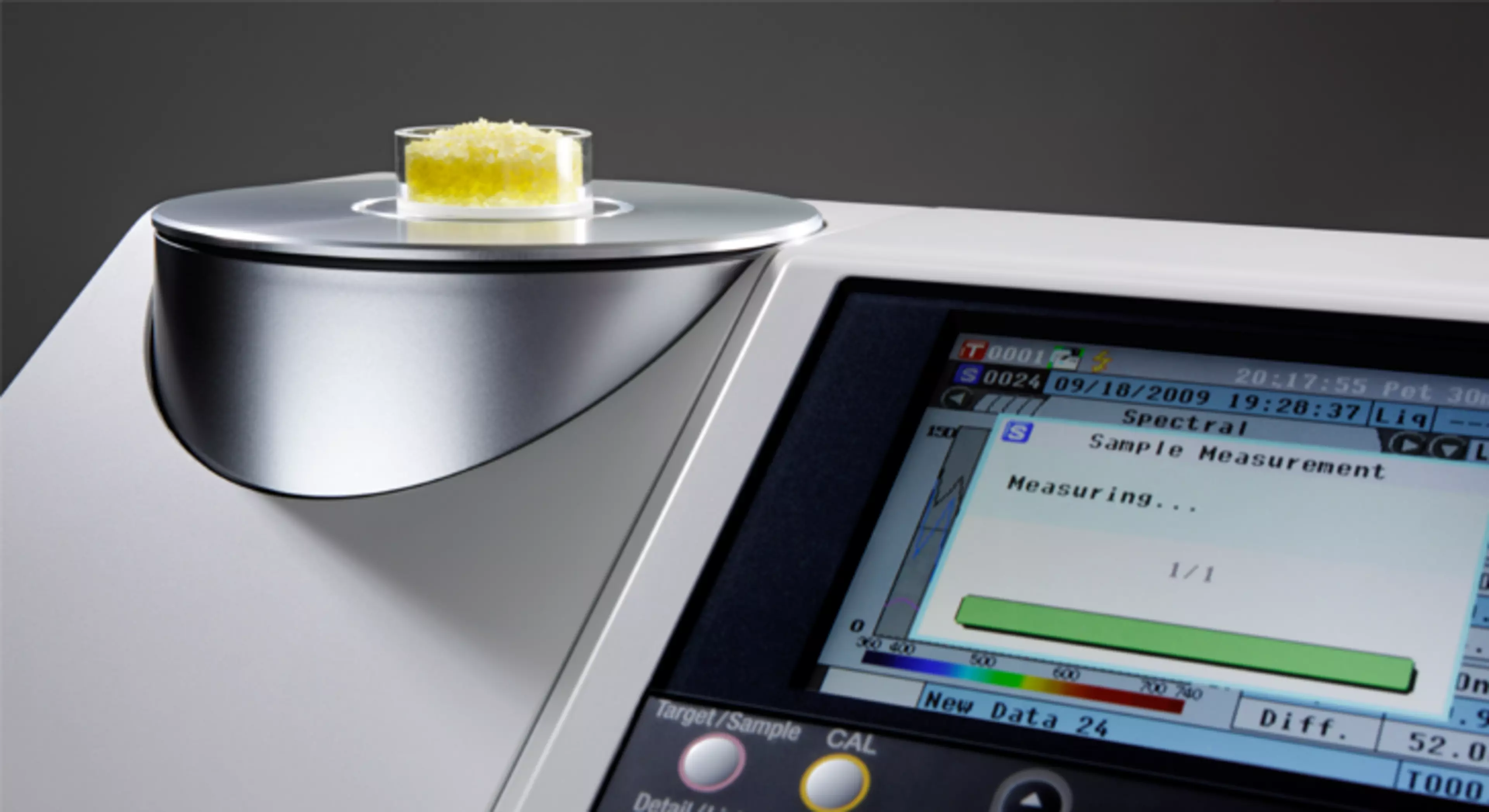

Benchtop spectrophotometer with built-in display, user friendly interface, and measurement wizard to cut operator errors. Can also be used connected to a PC for more versatile and detailed reporting. The top facing measurement port of the CM-5 simplifies the process of measuring powdered samples by using an optical glass petri dish.

CM-17d Portable Spectrophotometer

The vertically oriented CM-17d or CM-16d portable spectrophotometer can use a glass measurement aperture to allow measurement directly onto or into powdered samples, the granular material attachment or vertical levelling jig with cell holder . The instrument can be connected to colour data software or operated using the built-in display.

Applications

Measurement of Powdered Cosmetic Products

Using the CM-5 and petri dish set, operators can quickly achieve accurate measurements of colour. The spectrophotometer can be connected to software to allow for storage and statistical analysis of colour measurement and colour difference data.

Digital colour data software will allow the producer to build a library of colours to colour match against or for quality control reporting colour and colour difference against specification and previous batches.

Measurement of Cosmetic Powders on Skin

Powdered cosmetics will always be used in combination with the customer’s natural tones. The CM-700d is wideley used for skin measurement and can be used to measure cosmetic powders on skin or for other measurements at suppliers, customers, or within production.

The CM-700d can be connected to colour data software and its ergonomic design make it easy to position on skin for accurate measurements.

Measurements of powders can otherwise be made using a powder press or glass light projection tube.

Measurement of Pharmaceutical Powders

Using the CM-5, measurements can quickly be made for accurate colour data either for colour QC or in development. By connecting to the software, instruments can be easily configured for whiteness or yellowness measurements alongside any custom created indices or colour difference equations.

Ask our experts