Display Measurement Solutions for the Consumer Electronics Industry

Konica Minolta, along with group companies Radiant Vision Systems and Instrument Systems GmbH offer cutting edge display quality measurement solutions to the consumer electronics industry. We supply innovative, accurate, and traceable solutions for characterising brightness, colour, uniformity and more to ensure the quality of display technology. Displays, single components and panels must be objectively tested at all stages of the manufacturing process. The measuring instrument has to simulate the human eye or visual system and to fulfil a number of tasks:

- Standard evaluation of ergonomic and safety-relevant characteristics

- Determining product specifications

- Product and technology optimisation

- Quality control

Our solutions support test and validation of all display technologies:

- Television

- Portable electronics (mobile phone, tablet, camera, smart watch)

- Domestic, professional, and healthcare monitors

- Integrated display technology

- Projection systems

- AR/VR/MR systems

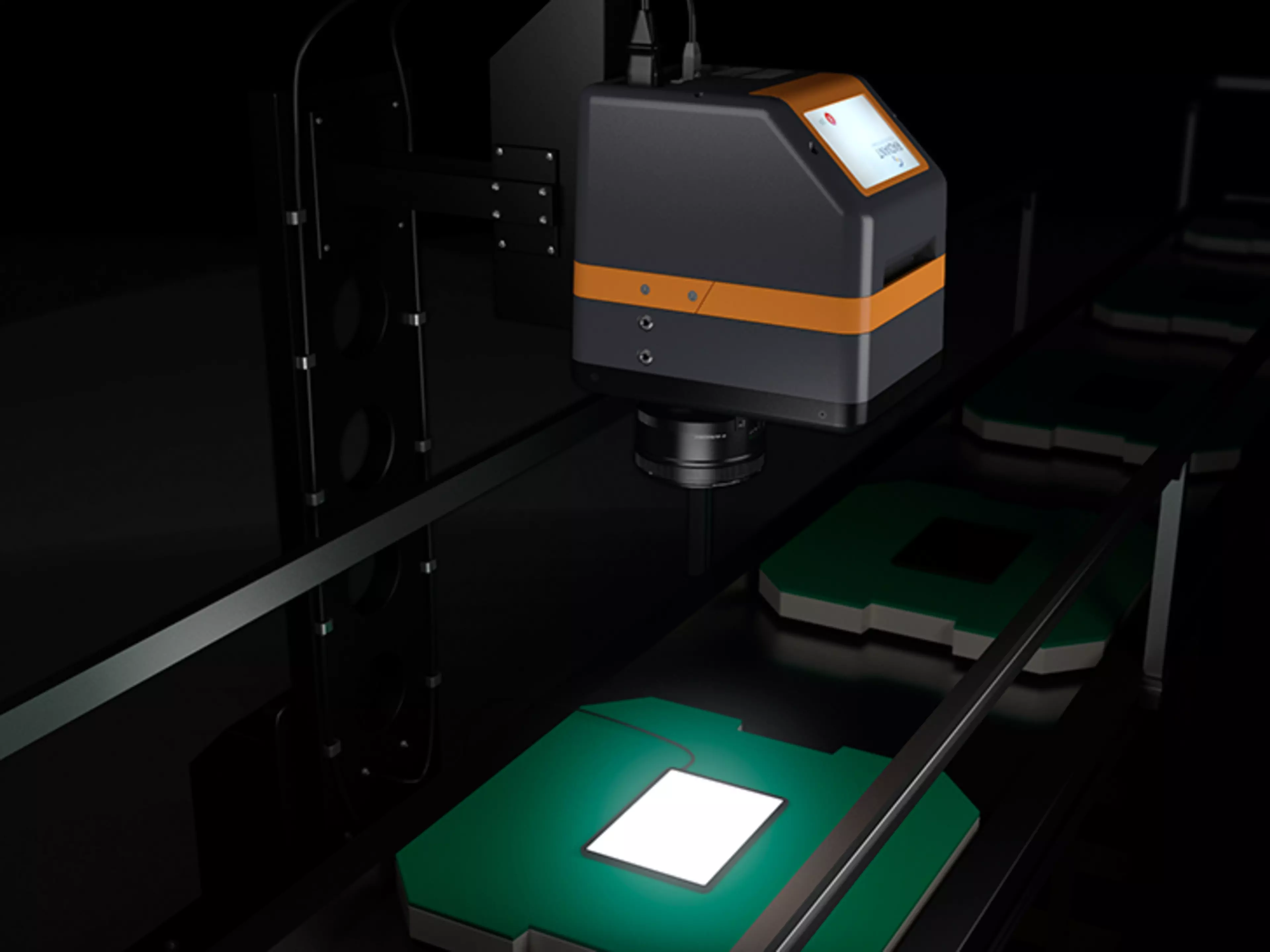

Display technology has become an increasingly crucial element of customer experience and user interface. New technologies such as OLED and µLED enable new form factors, designs and applications. To meet consumer expectation, test and measurement systems should be able to accurately characterise existing and emerging technologies whilst improving TAKT times and offering opportunities to simplify integration, automation, and versatility. Our accredited test lab guarantees independent, reliable and comparable readings, directly traceable to the reference standards of the National Metrological Institute PTB (Germany) and NIST (USA). A direct comparison of measurement results is thus always possible, regardless of the specific metrological implementation and locations of measuring stations or production lines.

Measurement systems ensure the fast and accurate validation and calibration of display characteristics including:

- Brightness and Contrast

- Colour Gamut and Accuracy

- Uniformity and Homogeneity of image content

- Pixel Defects

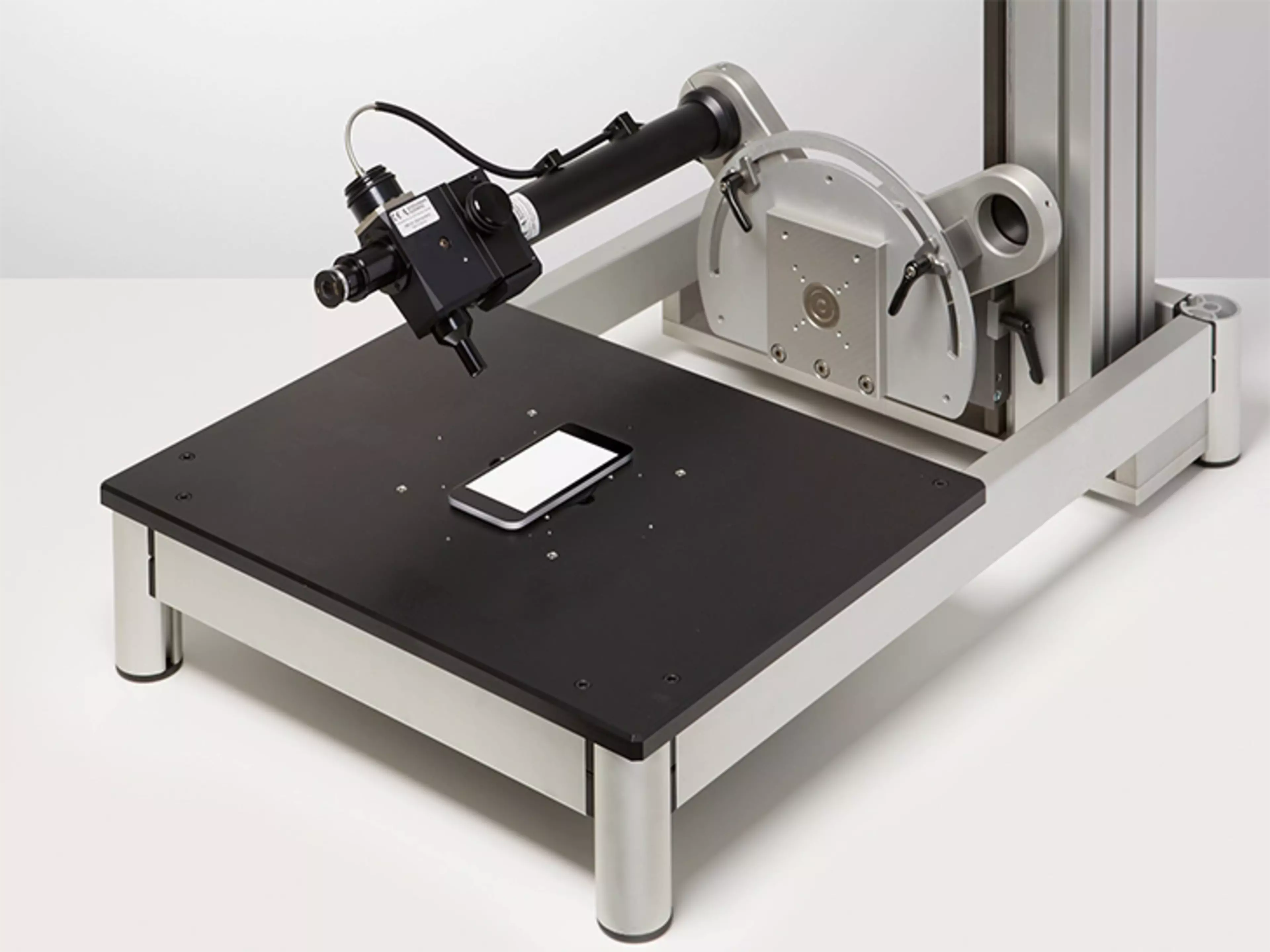

- Influence of viewing direction on contrast, colour, luminance

- Flicker and switching times

- Influence of ambient light and temperature on the optical properties.

Requirements, benchmarks and standards may be different according to the application. Our experienced team can help you to select the correct solution and support you through the installation and lifecycle of the instrument.

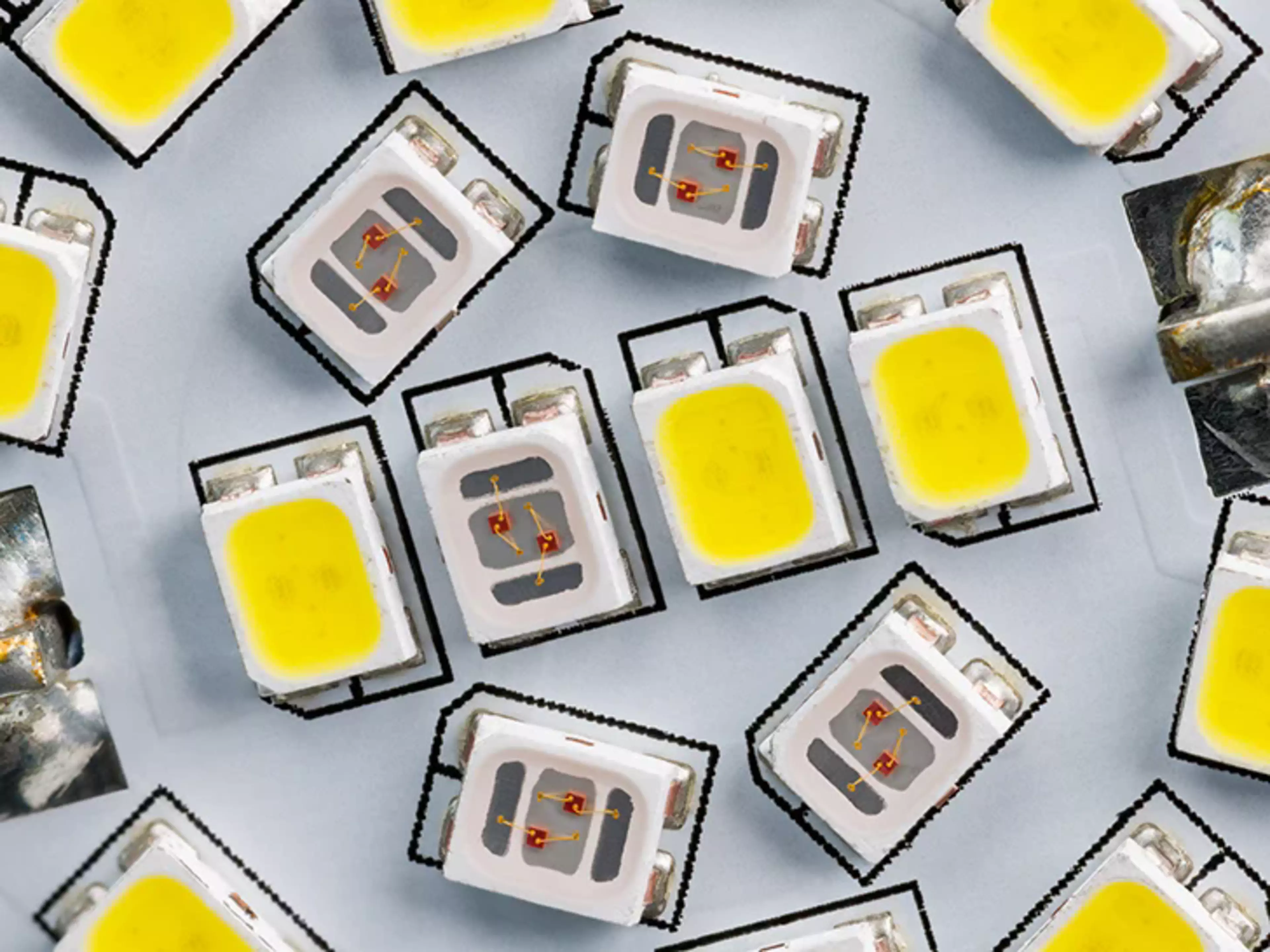

Scalable solutions are available to help organisations and their wider value chain to benchmark, specify, produce, inspect, and calibrate all manner of display technology including the accurate characterisation of emerging technologies such as:

- OLED panels

- Micro LEDs

- VR headsets

- Curved displays

- HDR displays

- UDC (under-display cameras) and more.

The sales and support network of the Konica Minolta group of companies can support your project on an international or global scale.

The Konica Minolta group has expertise and measurement technologies that enable our customers to improve quality, optimise processes, improve consistency, boost customer satisfaction, reduce waste, reduce costs and more. Our measuring instruments are used in the production lines of many of the consumer electronics industry's most highly regarded and cutting-edge display products.

We have a global reach, with local sales and expertise to assist you in establishing a successful display measurement system. Whether between supply chain partners, in development, in production or in QC, our teams can deliver a solution that meets your needs, and partner with you to scale that system as those requirements grow.

Our solutions are supported by a dedicated team experienced in installation, training, and customization of the solution. An extensive global network of authorised service facilities ensure that your instrument is maintained, accurate, and traceable all year round.

Benefits

- Reduce production time, costs, and waste: Improve takt times whilst also improving defect detection and configuration by implementing a cutting edge, automated inspection and calibration solution that can keep up with manufacturing processes.

- Push the boundaries of new technologies: Development teams can benefit from cutting edge measuring instruments with the highest standards in accuracy, from the blackest blacks to the brightest pinks and the boldest blues, allowing producers to continue to wow consumers and industry alike.

- Increase perceived value: Specify & control components and processes, target improvements and consistency with supply partners, elevating consumer perception of quality and value.

- Versatile measuring solution: Systems can be adapted for different size display and parallel display technologies.

- Low-cost display production due to short measuring times, automated 24/7 use, stability in the harsh production environment in terms of temperature, dust, humidity, etc.

- Customized product adaptations for new applications coming with a powerful analytical software for the reference lab.

- Objective evaluation of display characteristics at all stages of the manufacturing process with test systems simulating the human eye.

Example Applications

- Accurate, traceable and automated inline inspection and real-time configuration systems for all display technology production, from cutting edge TVs to smartwatches.

- Meet customer expectations in the emerging technology of augmented reality and virtual reality display. Accurate, purpose designed metrology and software helps manufacturers evaluate products with pupil position measurement technology.

- Traceable systems for benchmarking suppliers and competitor products can help companies to find and maintain competitive advantage in what is a highly competitive market. With a deeper understanding of product quality and consumer expectation, producers can optimise production to deliver the right products at the right price.

Select from the categories below to learn more about solutions for display measurement for specific applications