Colour and Surface Measurement for Transparent Building Materials

Measure and control the colour and gloss of materials including glass, films, and plastics

Transparent building materials can pose additional challenges from a consistency and control perspective. Not only any colourants but also thickness, haze, and even small differences in the observer angle can impact the visual effect.

Konica Minolta Measuring Instruments and software offer customers a solution for accurate colour control of everything from raw materials to completed products. Colour measurement allows organisations to implement data driven process control and quality control procedures that improve output consistency, and produce accurate colour to specification and within tolerances, saving time and waste.

Digital colour data can be used to expedite the supply process, greatly improving the producer's ability to react to the market, reducing the risks and costs associated with producing, distributing, and maintaining physical standards.

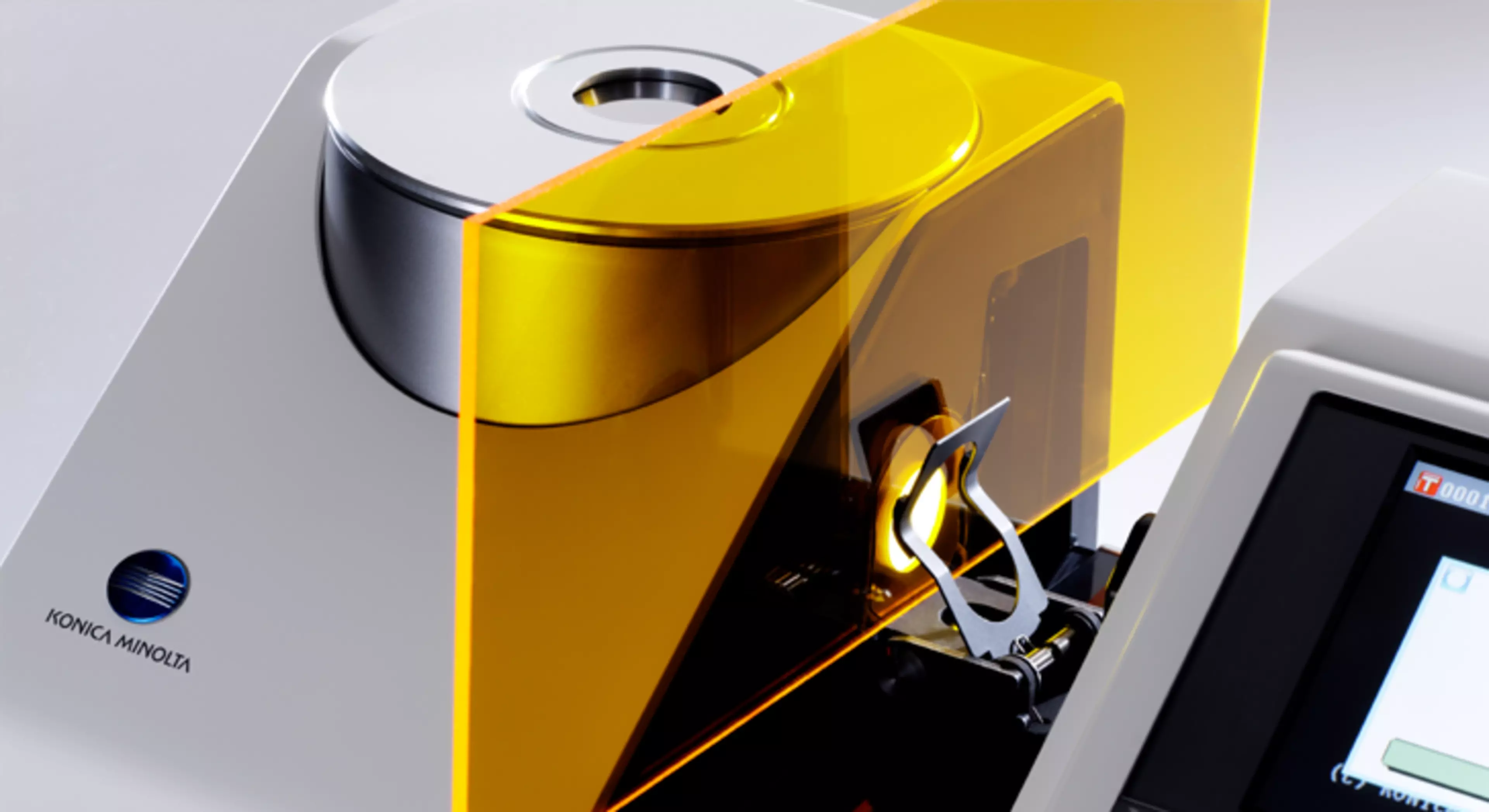

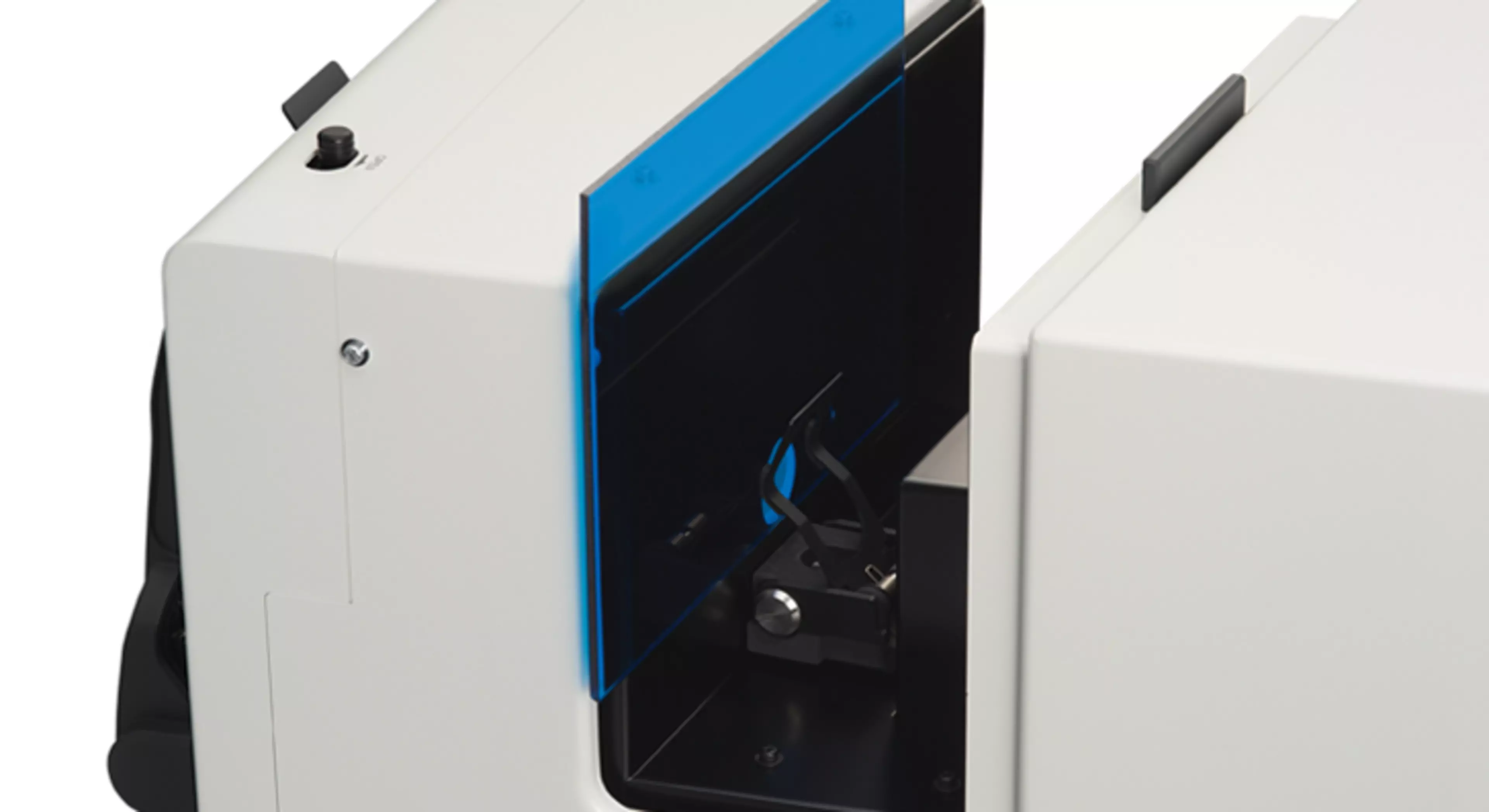

For transparent materials, only a benchtop spectrophotometer can measure in transmittance and provide data for haze. All of the benchtop instruments form Konica Minolta are designed with a large open sided transmittance chamber, so the decision ultimately will be driven by any additional features on the instrument, for example the built-in display and operator wizard of the CM-5 or the Wavelength Analysis and Adjustment features of the CM-36dG.

Our experts can help your teams to establish digital colour standards and colour difference tolerances that you can share with your supply chain partners. You can leverage the experience of our application teams to quickly establish repeatable, best-practice processes for colour and appearance measurement and control.

Colour control can help businesses to control processes and offer competitive advantage through improved consistency of finished product.

Konica Minolta Measuring Instruments and the team of specialists offer the expertise from hundreds of installations within this field, supported by a network of authorised service facilities in order to offer swift repairs, and to maintain the accuracy and traceability of these instruments year-round.

Benefits

- Improve certainty of production process, minimising rework, and maximising final finish quality.

- Reduce costs throughout the production process by measuring and optimising each step in the process.

- Improve consistency, set realistic and achievable expectations by benchmarking your own and competitor finishes.

Instruments

Applications

Ask our experts