Colour Measurement for Solid Foodstuffs

Colour measurement for development, process control, and quality control of foodstuffs

The consumer eats with their eyes, so improving the consistency of products and developing exciting and realistic coloured products will help a producer's products to compete on the shelf and improve consumer perception of quality on the plate. Inconsistent colours can damage the perception of a brand and lead to increased waste.

Our versatile benchtop instruments have many advantages for the laboratory setting as they are able to measure a greater number of sample types easily. Benchtop instruments have larger measurement apertures and include innovative new features, such as a sample viewer camera that aid in fast yet accurate work.

Our portable colorimeters are synonymous with quality control measurements and particularly in the food industry, where at this stage in the process spectral data is not required. A tristimulus meter provides an accurate and traceable alternative to a spectrophotometer, providing data that corresponds to the human observer whilst also being comparatively robust. Many food products with inhomogeneous colour can be best measured by the CR-410 which quickly provides data that correlates with human perception by averaging the measurement over its large 50mm measuring aperture.

Colour data can be used as a process control tool, and an indicator of flavour, freshness or degradation over time, or temperature.

Konica Minolta Measuring Instruments are widely used in the food industry, in development labs, at goods-in, in-line, or at quality control for virtually all solid foodstuffs such as breads, meats, cheeses, pasta, cakes, etc. Our solutions help organisations to produce consistent and appealing products, and generate valuable data that helps to save costs, cut waste, and improve the quality of products.

In recent years, the possibilities of automated inspection and measurement have greatly increased. Through Konica Minolta Group company SPECIM, we are able to offer our customers both laboratory and production hyperspectral systems that can perform a range of tasks for the food industry such as foreign object detection, fat content analysis, sorting, topping coverage, and packing inspection.

Benefits

- Reduce waste, and cut rejects and out of specification production

- Save time thanks to instrumental pass/fail or grading of colours to predefined indices

- Improve quality and produce a more consistent and appealing colour product by specifying and controlling production

- Improve safety by checking products in-line for bone, wood, and other foreign bodies

- Simplify quality control

- Generate actionable process control data

- Measure quantifiable data for product parameters

Instruments

Applications

Application Note: Fruit maturity evaluation through colour measurement

Portable spectrophotometer CM-17d with its viewfinder camera offers superior accuracy, easy targeting, and dependable performance in real field conditions for consistent fruit maturity evaluation.

Discover how the CM-17d is used by a research team in Japan to enhance measurement reliability and operational efficiency.

Measurement of Meat and Fish

Homogenous products such as duck or chicken can be measured using the 8mm aperture of the CR-400 and the optical glass or acrylic target mask to prevent ingress to the measuring aperture. The 50mm aperture of the CR-410 is more suited to in-homogenous products such as marbled beef, or fish. If desired, software can be used to create a user index allowing for user friendly sorting or grading, less subjective and faster than visual assessment and physical colour charts.

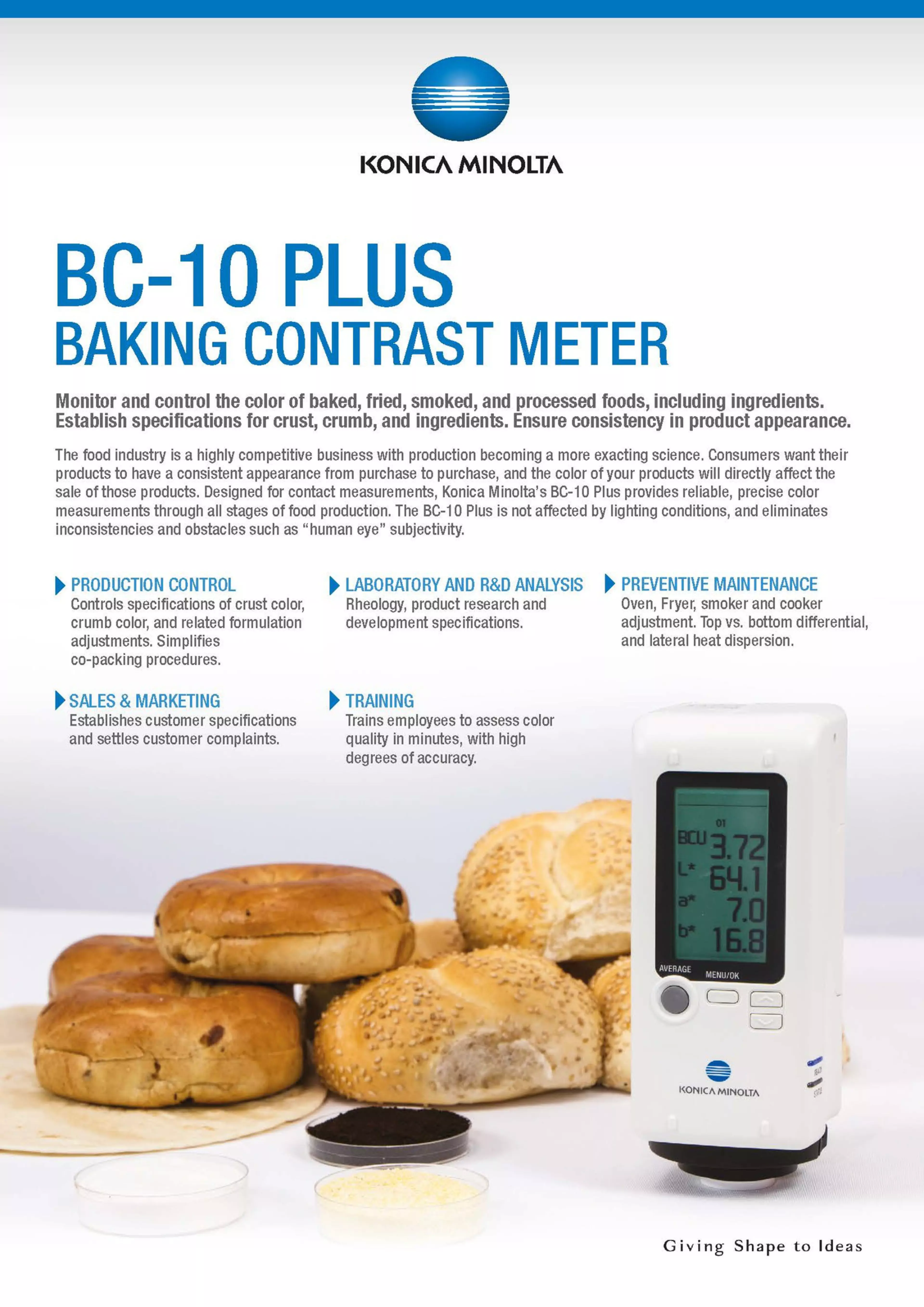

Measurement of Bread and Baked Products

Manufacturers of bread and baked products can utilise the purpose-built BC-10 Plus with 8mm aperture to measure either Baking Contrast Units (BCU) or L*a*b* colour directly on the device. This small and easy-to-use instrument offers users data driven process control and QC.

Ask our experts